How to Create a Reordering Rule

How to Create a Reordering Rule

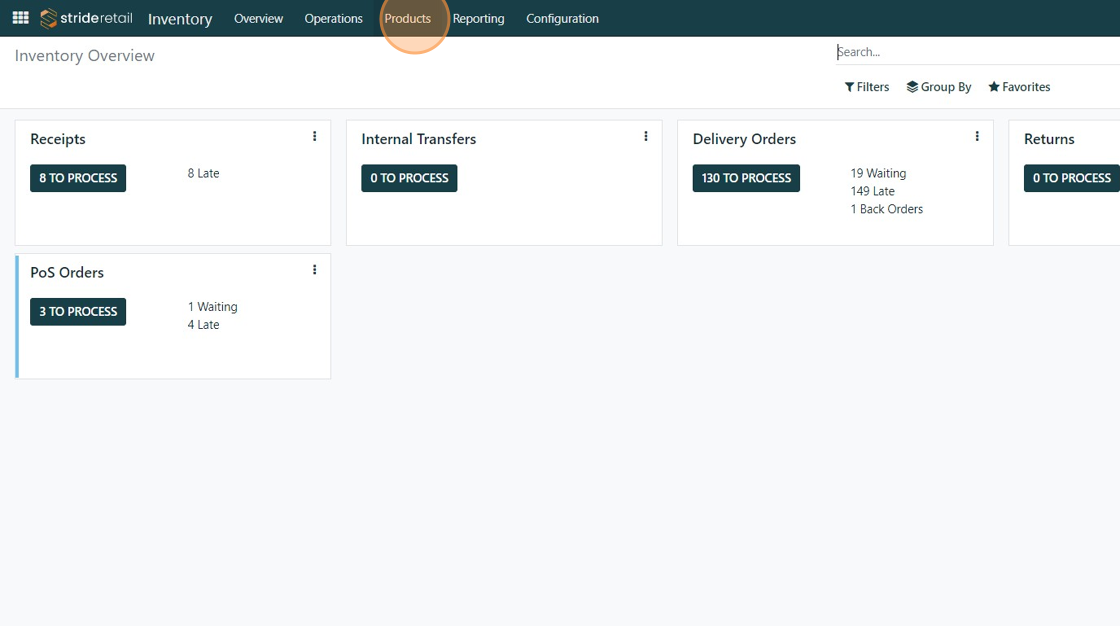

1. Go to Inventory

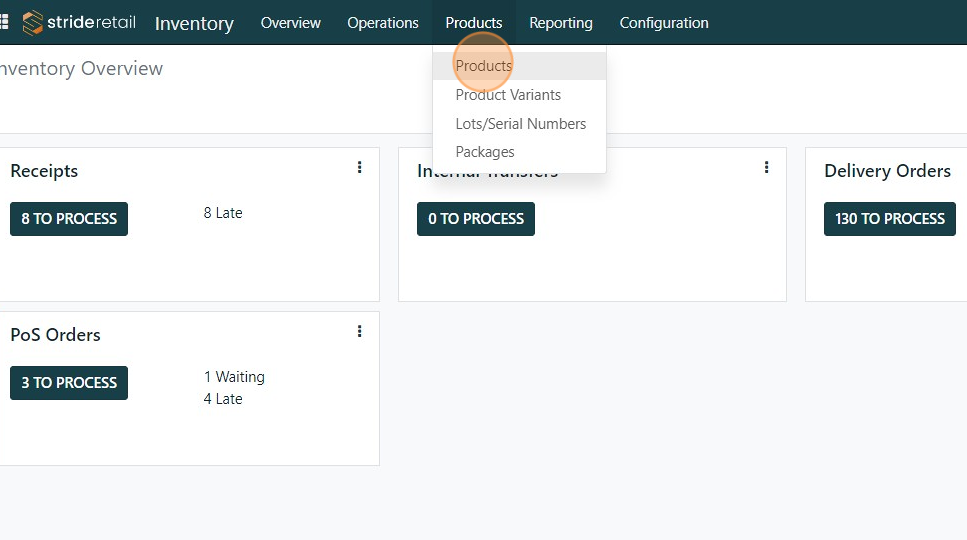

2. Click "Products"

3. Click "Products"

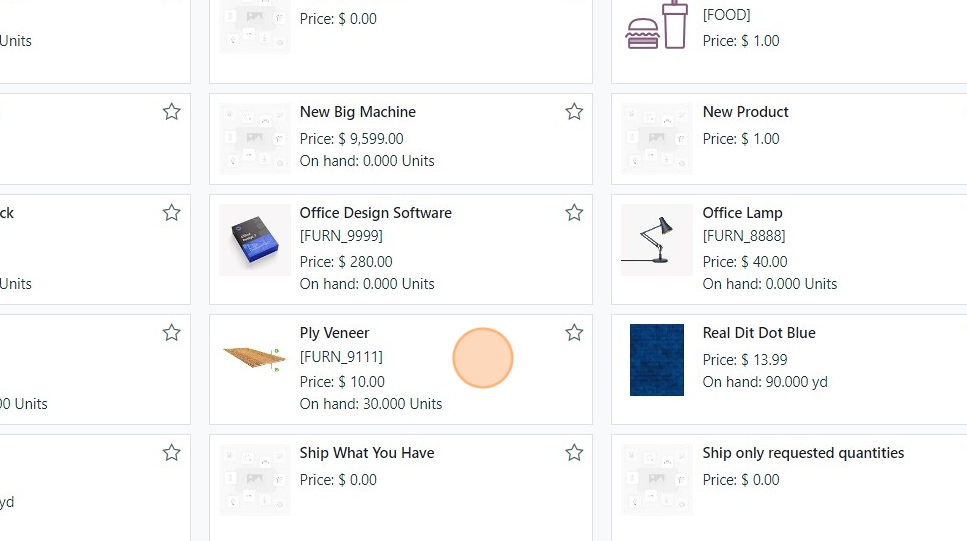

4. Navigate to your product

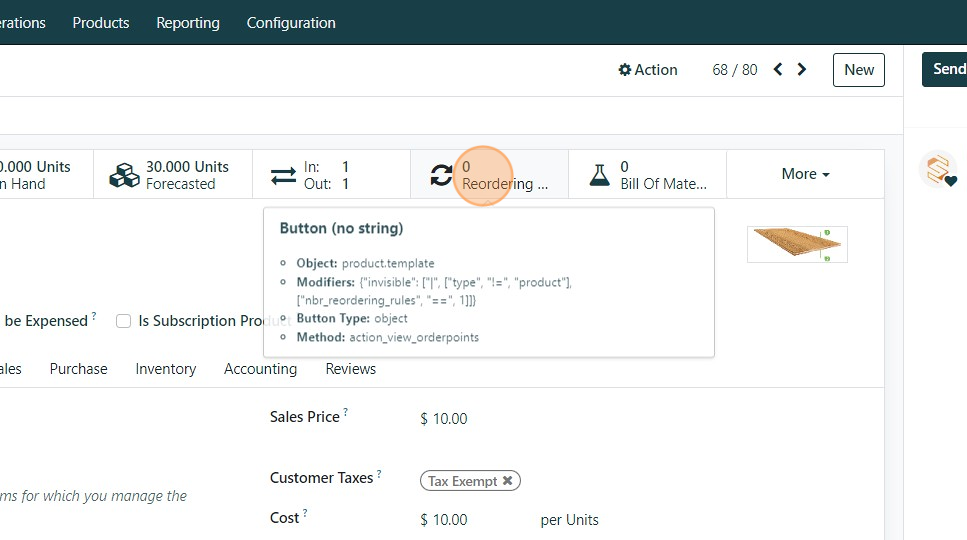

5. Click "Reordering Rules".

*Note - If a manual Reordering Rule has been created (ie an item has an on-hand quantity that is less than the forecasted quantity) this will say "Min-Max" not Reordering. This is because a manual rule has already been created.

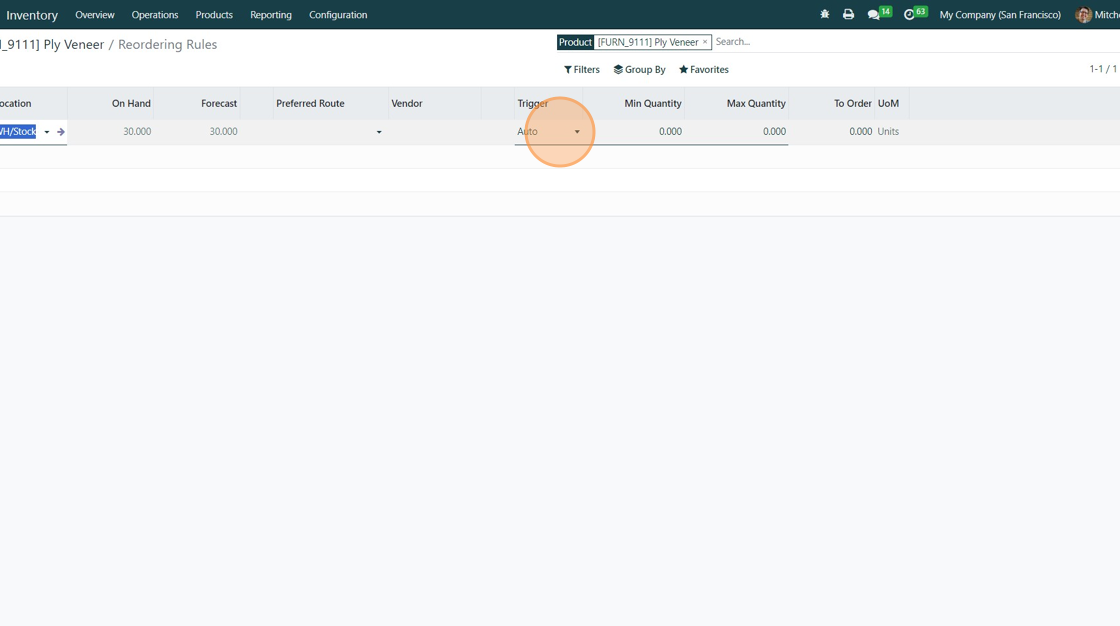

6. Click "NEW"

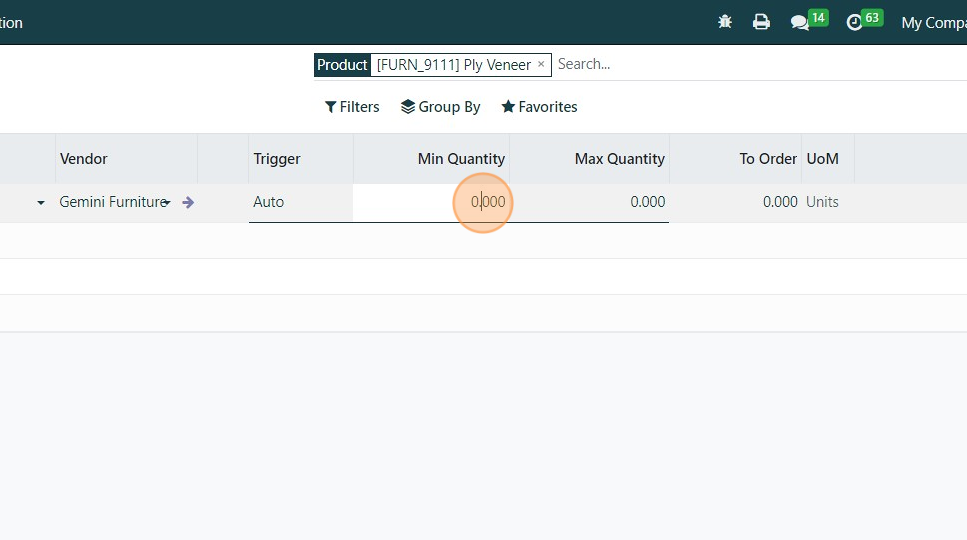

7. Click this dropdown to select "Manual" or "Auto".

Manual - no PO will be created. It will just be added to the "Replenishment Report"

Auto - if the vendor is set on the product card it will create a PO automatically for that vendor (or it will be added to an open PO for the specified vendor).

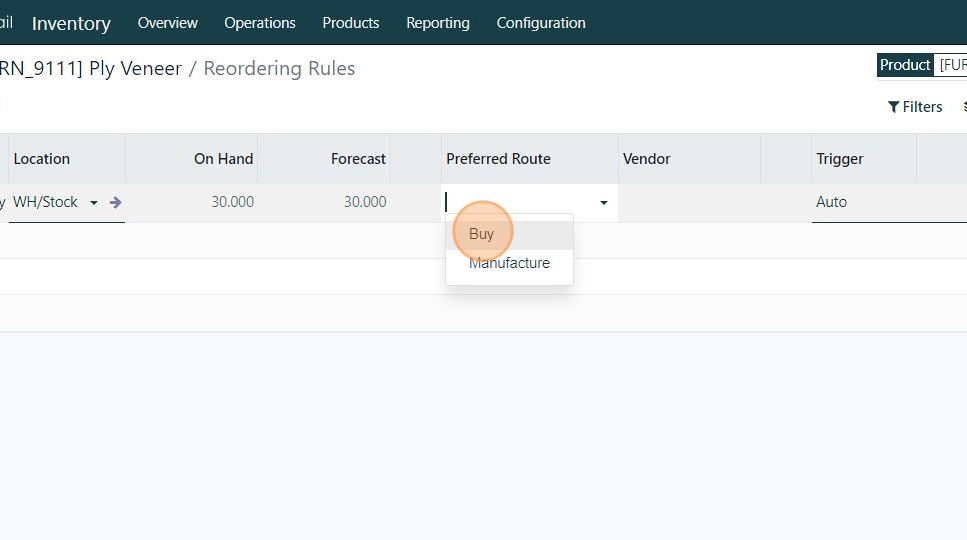

8. Click this text field and select your route.

- "Buy" creates a PO

- "Manufacture" will create an MO

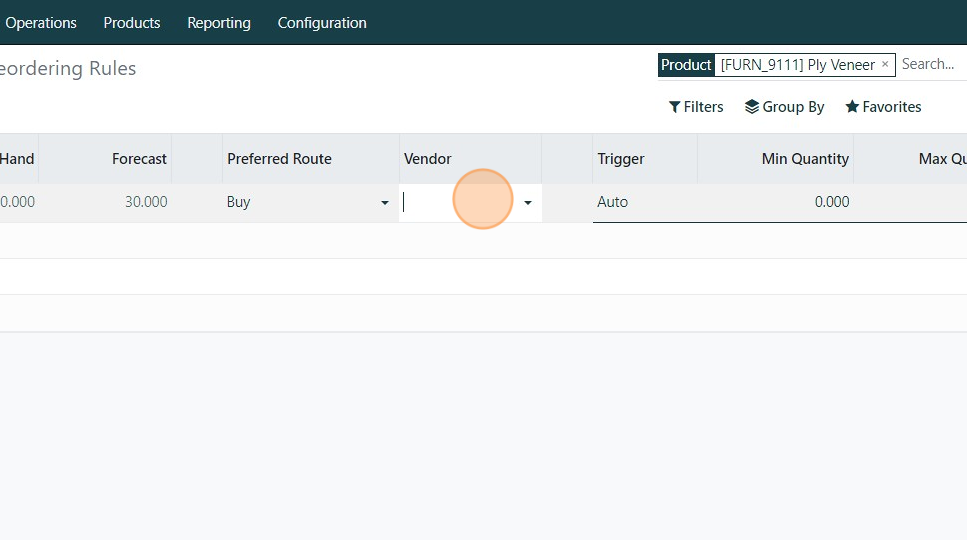

9. Click this text field to select the vendor. If there is no vendor outlined on the product card you will not be able to select the vendor.

10. Set the minimum quantity you want to maintain in your inventory. This is your "trigger point."

Set the Maximum Quantity. This is the "reorder max". In our case we entered 10 as the minimum quantity and "30" as the maximum.

This means if the product forecast falls below 10 it will trigger a PO amount to get the total back to the "Maximum Quantity."

11. Click "SAVE"

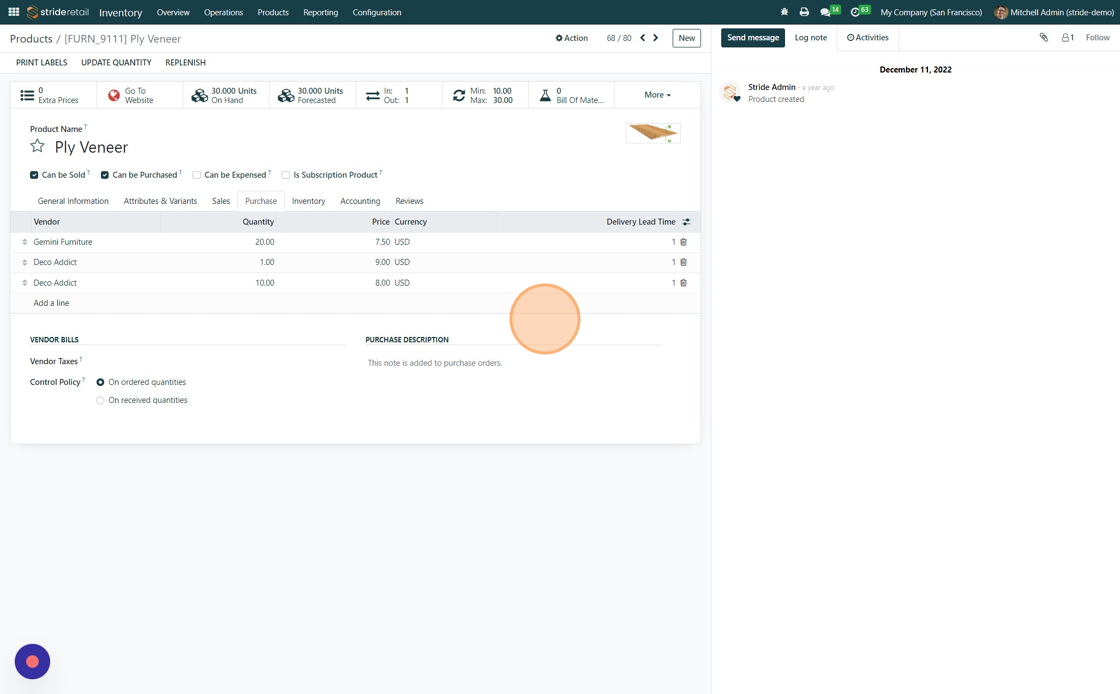

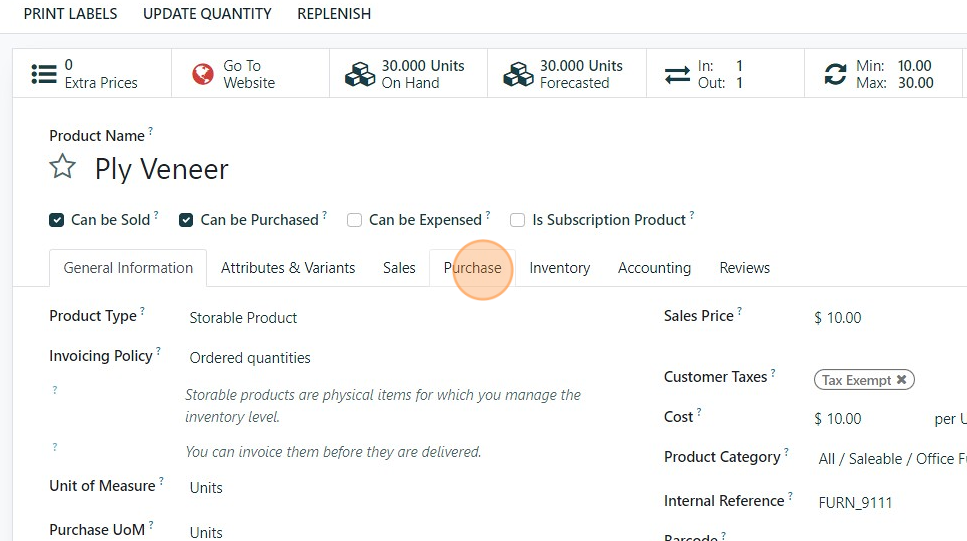

12. To set the vendor on the product card click your product in the "breadcrumb"

13. Click "Purchase"

14. In this example we already have 2 vendors set and different price breaks for different quantities.

The system will order based off the cost and lead time you set for each vendor. If you want it to order for cost only set the delivery time the same for each vendor.